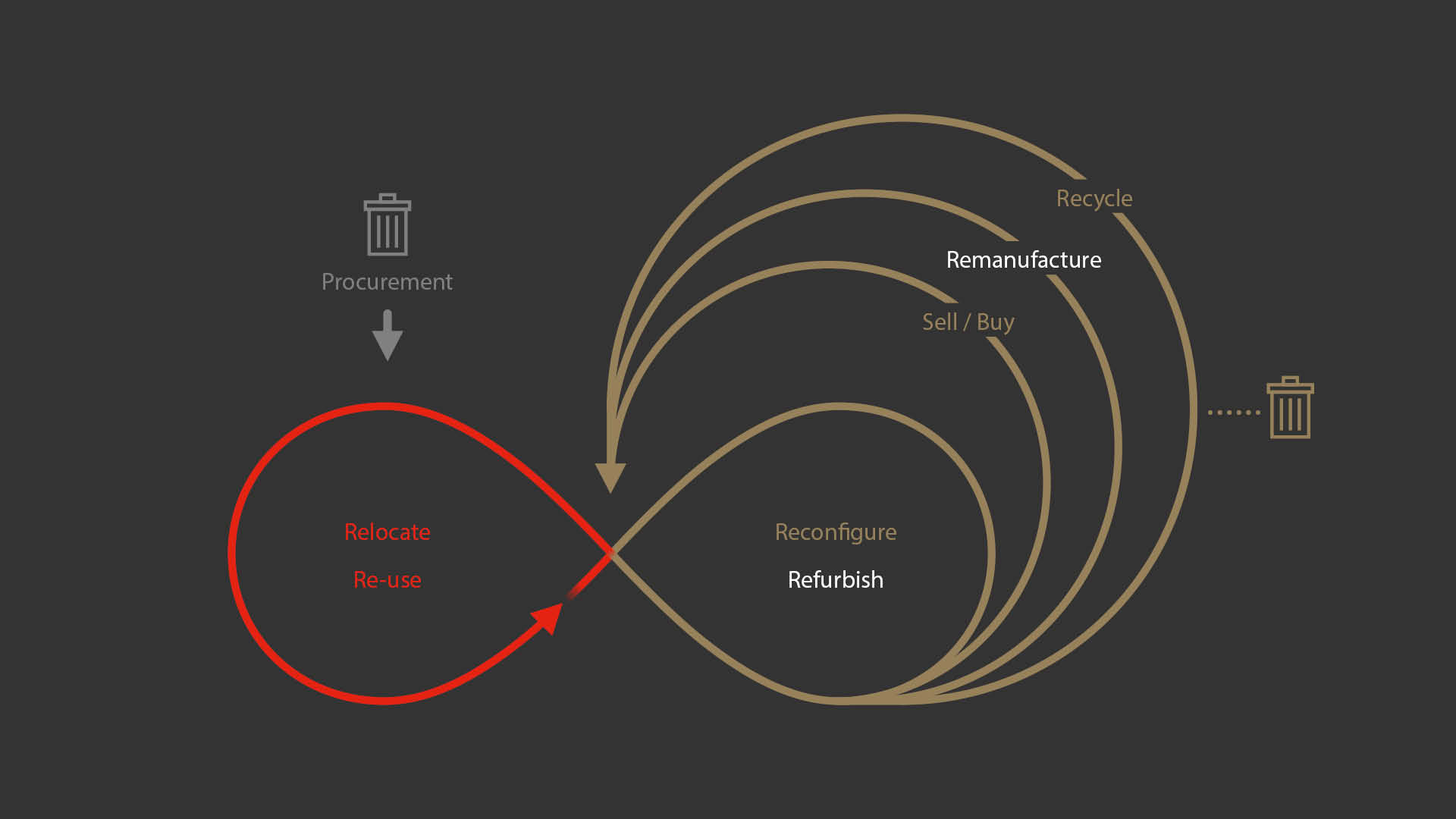

Egans 7 element circular economy model includes our refurbish and industry first remanufacture process, breathing new life into unwanted corporate, tertiary and government furniture whilst keeping over 120,000 assets in the circular economy annually.

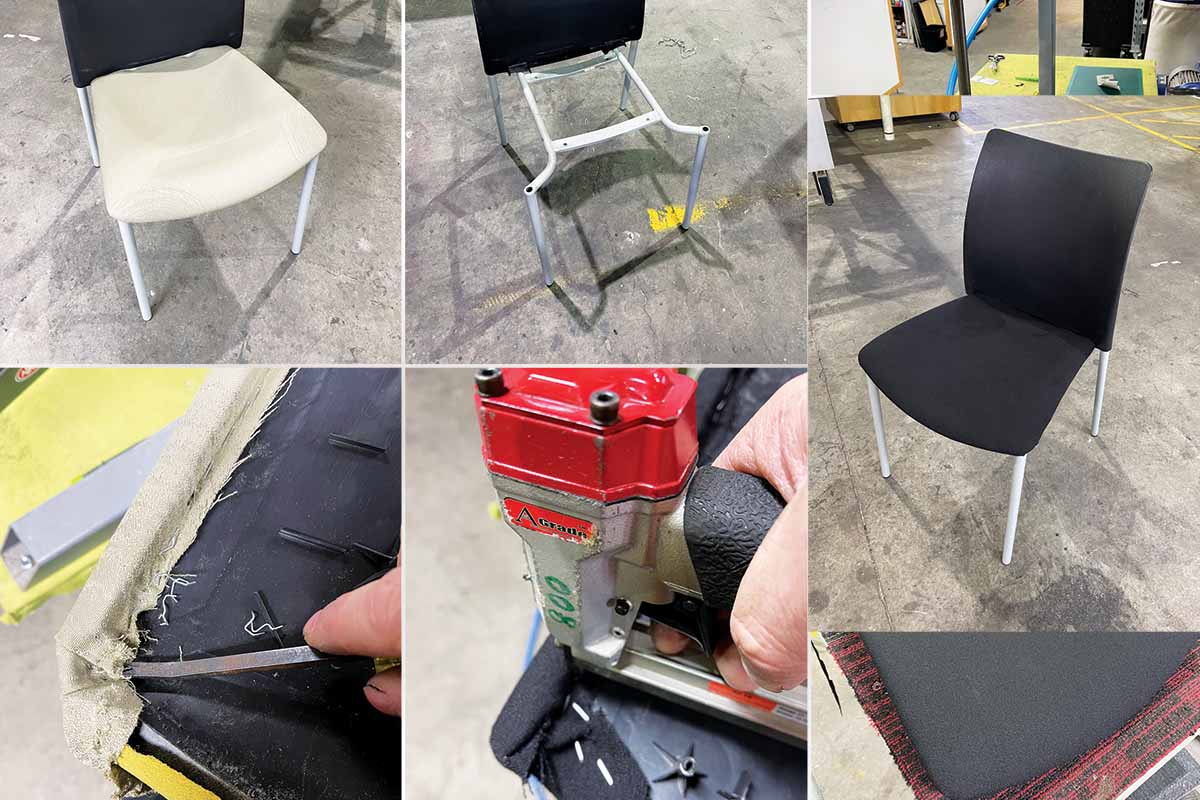

Refurbish

The fabric and soft material comprising office chairs and workstation screens is often the first to degrade. Rather than recycling the raw components and sending the non-recyclables to landfill, our first objective is keeping furniture in the circular economy.

We reupholster chairs and workstation screens in our circular workshops, either for existing clients to reuse through our reuse stores or to resell through our circular resale channels.

In this example, Egans:

- Polished the legs and bases of the chairs.

- Reupholstered the fabric.

Remanufacture

Our industry first remanufacture process remanufactures incompatible bases, legs, screens, and tabletops into cohesive workstations. Previously unsalvable components from multiple defits are remanufactured into new fitouts.

In this example, Egans:

- Remanufactured legs, bases, tops and screens from multiple workstation sources.

- Powder coated frames.

- Replaced Perspex screen with Eco-panel.

- Powdercoaed the brackets, screen and legs.

- Re-edged the top.